The Role of 3D Printing in Injection Molding

Additive manufacturing is another name for three-dimensional printing or 3D printing. The technique of printing and fusing layers of material to create three-dimensional things from a computer design is known as 3D printing. The term refers to creating a 3D-printed item using “additive processes.”

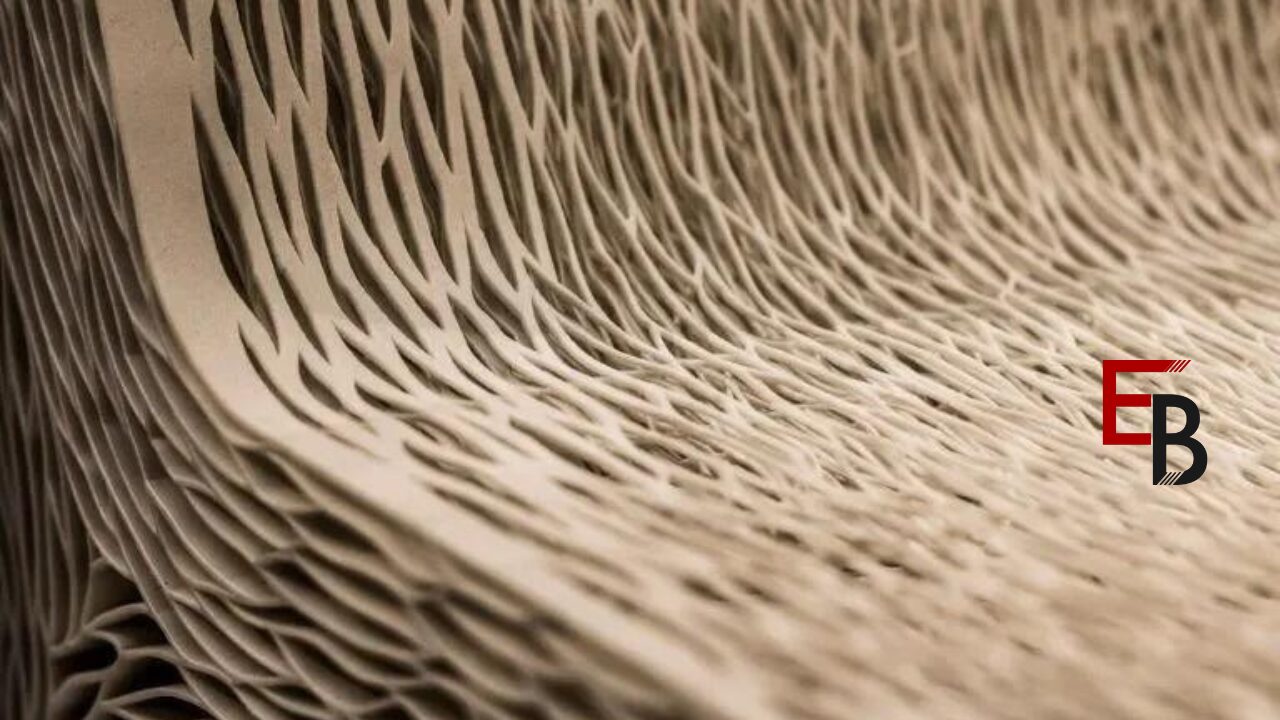

A component or an entity is constructed layer by layer using an additive method. Every one of these levels represents a finely cut cross-section of the element.

How 3D Printing Can Help You?

Previously, 3D printing technology was unable to produce precise and well-finished objects. Also, the materials needed to be more robust to withstand frequent usage. Because of this, the prototype stage of product life cycles has been where 3D printing has been most beneficial.

However, 3D printers can now achieve a far superior surface polish because of recent printing technology and materials advancements. And there is a far greater variety of materials.

As a result of these developments, 3D-printed plastic molds for small-scale manufacturing have been tested.

With the new features of 3D printing, plastic molds are a fantastic substitute for conventional metal molds. The following are the key features of 3D printing that are most important for creating injection molds:

- Less money out of pocket than with machined metal molds.

- Lower expenses associated with supplies.

- Quicker response times.

- Quicker and less expensive design iterations and modifications.

- More complicated and intricate geometries are conceivable.

- Even novices can launch a small-scale manufacturing company.

The Change That 3d Printed Molds Brought About

In the injection molding sector, 3D printing is causing a stir. Although traditional metal molds are renowned for their dependability, they are frequently expensive and require lengthy manufacturing schedules. On the other hand, 3D-printed molds are becoming a viable substitute that saves a lot of money and effort.

The production industry has transformed thanks to the development of 3D-printed injection molds. Thanks to developments in 3D printing technologies, what was formerly a time-consuming and expensive practice is now more accessible. These technologies make it possible to produce molds quickly and affordably, which is very helpful for those who develop injection molds but lack the funds for significant upfront expenses.

Moreover, the speed and versatility of 3D printing make it perfect for creating molds with complicated configurations and elaborate patterns, which would be costly and challenging to do using conventional techniques. This feature is helpful for individuals new to injection since it enables quick prototyping and simple tweaks without the need for costly tooling or lengthy downtimes.

One of its main advantages is the simplicity with which 3D printing can handle intricate mold designs. By creating complicated and one-of-a-kind forms that were previously difficult or impossible to make, 3D-printed molds bring up new possibilities for product design and functioning.

A larger audience may now access this technology because of the popularity of desktop 3D printers. With 3D-printed molds, small enterprises and startups may now produce parts on a smaller scale, lowering their reliance on outside suppliers and giving them more control over the manufacturing process.

However, it’s crucial to remember that materials used in 3D printing differ from those used in conventional molding. They select a printing substance appropriate for the molded part’s intended use. The good news is that more alternatives are now available that combine the strength and durability required for high-quality injection molded products, thanks to continuous breakthroughs in materials science.

The injection molding industry is changing as a result of 3D printing. Its cost, effectiveness, and capacity to create intricate and sophisticated molds make it a priceless instrument in modern production. Large manufacturers are no longer the only ones using this technology, giving inventors and producers worldwide a platform to engage in what was formerly a very exclusive industrial sector.

In summary

It is impossible to overestimate the impact of 3D printing on injection molding innovation. Traditional manufacturing techniques have been completely changed by this technology, which provides answers to frequent problems and inefficiencies in the injection process. Conventional techniques might have flaws, distort with prolonged usage, or cause issues when removing a part from the mold, but 3D printing offers creative fixes and substitutes.

Despite the fantastic advancements, it is essential to recognize that 3D printing has a learning curve. It’s still necessary to deal with common injection-related problems, including pieces trapped in the mold or uneven finished goods. However, these little drawbacks will be solved and enhanced over time as technology develops.

Regarding cost, speed, and design flexibility, 3D printing techniques outperform traditional production processes regarding molds. This advancement is about more than simply solving the past; it’s also about laying the groundwork for the next advancements. Injection molding calls for exact specifications and intricate processes, and 3D printing technology is rising to satisfy these demands with ever-greater skill.

Injectable molding 3D printing has a bright future ahead of it. Technology is becoming more accessible due to ongoing improvements for large-scale manufacturers, people, and small enterprises. This democratization of manufacturing technologies is a giant step towards a day when everyone may realize their ideas without facing exorbitant expenses or obstacles to entrance. This optimistic perspective, which promises an exciting future for sectors globally, is based on the observable progress made thus far.