Why Your Optical System Can’t Compete Without Diffractive Optical Element Design

Designing modern optical systems isn’t easy. Managing lasers, shaping beam profiles, and meeting ever-stricter performance demands has become a constant engineering challenge. And when you think you’ve got it figured out, boom, diffraction, aberrations, and low efficiency throw everything off again.

That’s precisely where the Diffractive Optical Element (DOE) design steps in.

Whether you’re tackling beam shaping, optical communication, photonics, or laser projects, this guide delivers the insight you’ve been seeking. For engineers, system designers, or anyone enhancing an optical setup, these five minutes could be your most valuable investment today.

What is Diffractive Optical Element (DOE) Design?

Consider the diffractive optical element as a device that controls light diffraction rather than flexing it as would an ordinary lens, but also bending it in a staggeringly precise manner by case defining.

Engineers do not simply select lenses or mirrors in the DOE design process; instead, they design patterns that phase shift incoming light.

Microscopic patterns within DOEs can divide, sculpt, or direct light beams with efficiency that conventional optics can’t match.

And here’s the best part: DOEs are thin, lightweight, and fully customizable. That’s why they’re quickly becoming a go-to solution for the most advanced optical systems in the world.

Why You Should Rethink Traditional Optics

You know the pain: building an optical system with refractive components means fighting chromatic aberration, stacking lenses, increasing weight, and compromising on performance.

But with a well-executed diffractive design, you can:

- Reduce or eliminate chromatic aberrations

- Minimise the size of your system

- Improve diffraction efficiency

- Handle complex beam shaping with a single element

- Save space, cost, and alignment headaches

It’s all about rethinking what’s possible.

How Beam Shaper Design Fits In

Let’s say you need a flat-top, uniform laser beam. That’s tough with regular optics.

Beam shaper design using DOEs makes it achievable and reliable. You can shape a laser beam into almost any pattern: top-hat, ring, line, cross, or even complex custom forms. Perfect for applications like:

- Laser micromachining

- Medical laser treatment

- Optical trapping

- Sensor calibration

- Imaging systems

Want uniform intensity? Are you looking to divide a single beam into several precise points? DOE-based beam shaping provides the control you need and maintains consistency across your wavelengths.

What Makes DOE Design So Effective?

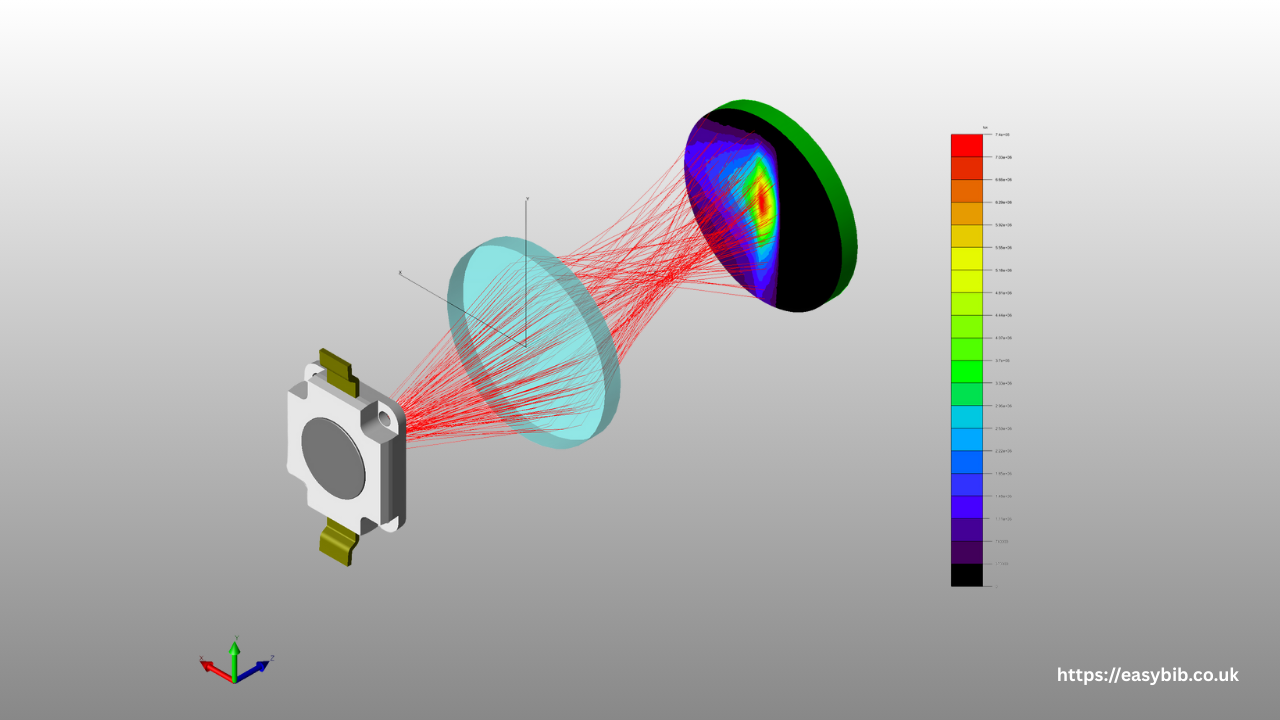

The true strength of diffractive optical element design comes from precise, simulation-driven modelling. This isn’t trial and error. It’s precise modelling using advanced optical software that predicts how each groove, line, and curve will affect the light passing through.

Every DOE is built for your wavelength, beam profile, and system specs. That level of customisation leads to:

- Higher diffraction efficiency (more power where you need it)

- Compact, low-weight designs (ideal for space-limited systems)

- Flexible integration into existing setups

- Better performance in optical communication and photonics

This is why you’ll find DOEs in everything from satellite sensors to advanced microscopes.

Why Simulation Matters

Without an accurate DOE simulation, every design choice is little more than a guess. In optics, incorrect assumptions can lead to beam distortions, efficiency loss, and system failures.

That’s why the design process is everything. It requires a deep understanding of diffraction, laser behaviour, materials, and optical software to get it right.

You can’t just “try a few grooves and see what happens.” You need precision from day one.

Why You Should Care (Even If You’re Not a Designer)

You may be wondering, ‘I’m not the one creating the DOE, so why should it matter to me? Why should I care?”

Knowing how a DOE works and what it can do helps you ask the right questions, choose better suppliers, and build more intelligent systems.

And if you’re trying to get ahead in the photonics or laser world, understanding DOE capabilities gives you a competitive edge most engineers don’t even realise they’re missing.

Final Word:

If you’re building anything involving lasers, beam shaping, or optical communication, then diffractive design isn’t optional; it’s essential.

Don’t let old-school optics hold you back.

You’ve got goals. You’ve got specs.

Now, you need a solution that can keep up.

Talk to an expert today. Let’s shape your beam the right way, from the start.

READ MORE

FAQs.

Can DOE design really fix the issues I’m having with my beam?

Yes, if done correctly. From beam shaping to correcting chromatic aberrations or minimising diffraction losses, DOEs deliver customised solutions beyond the reach of conventional optics.

Isn’t this technology overkill for smaller or mid-range optical systems?

Not at all. That’s the beauty of DOEs. They’re compact and cost-effective, especially for systems where space and weight are a concern. Small teams utilise them frequently — with notable results.

What if I don’t know exactly what design I need?

That’s okay. Most people don’t. The smartest step is consulting an expert who can translate your system needs into the right design or component choice. Don’t wait until you hit a wall.