Stop Overpaying for Spare Parts: How 3D Scanning and Printing Can Save You Time and Money

If you’ve ever had to replace a machine part, you know the frustration—long lead times, sky-high OEM prices, and endless back orders. What if you could skip the middleman and make the part yourself?

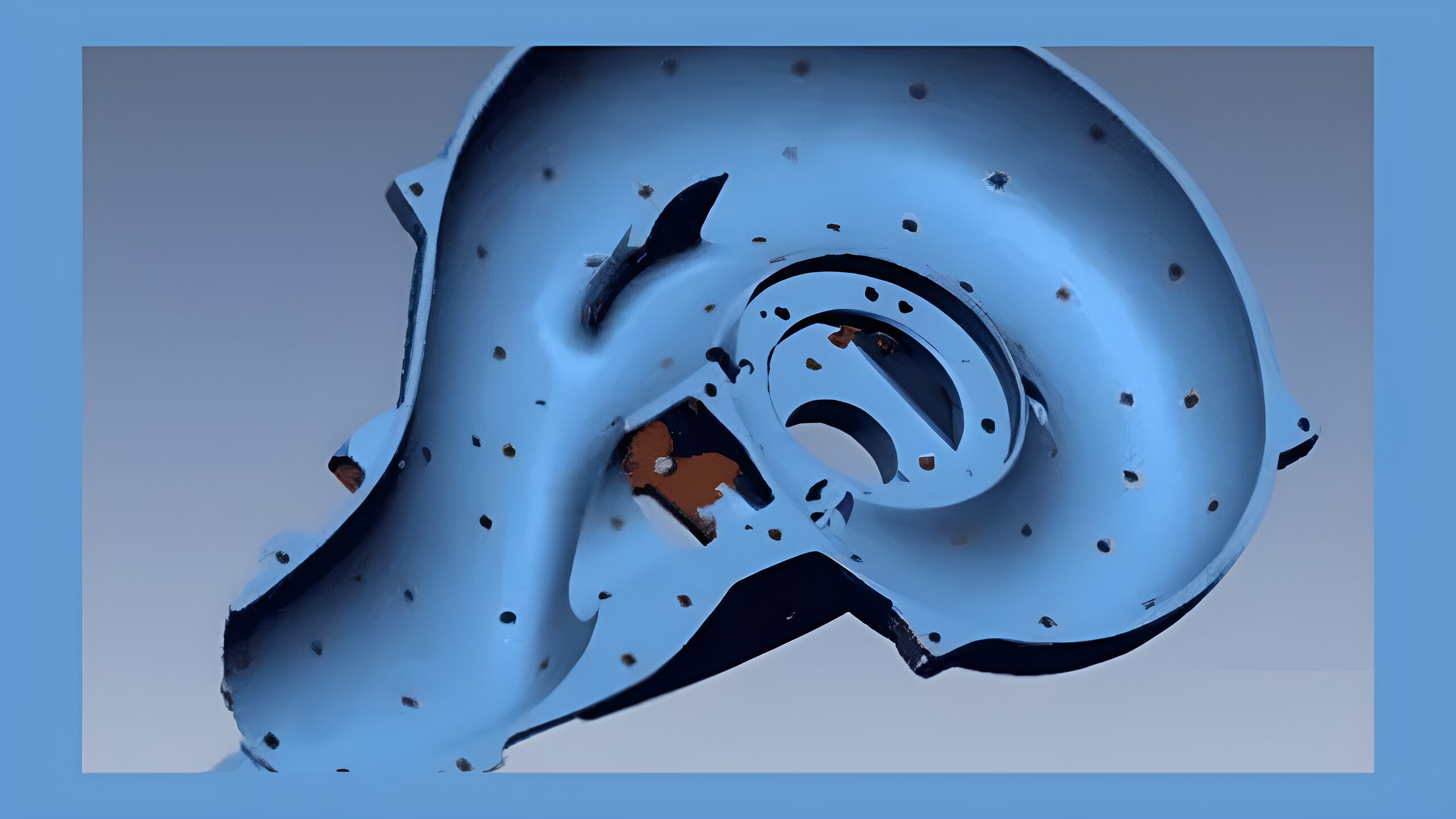

With 3D scanning and printing, that’s now a reality. Companies like RapidMade are helping businesses digitally capture and reproduce parts with pinpoint accuracy, eliminating the need to rely on expensive, slow-moving suppliers.

How It Works

1️⃣ Scan the part – Using high-precision 3D scanners, a digital model is created in minutes.

2️⃣ Reverse engineer – The scan is converted into a manufacturing-ready CAD file.

3️⃣ Print on demand – The part is 3D printed in plastics or metals, often within days.

Why It’s a Game-Changer

✅ Save up to 90% vs. OEM pricing

✅ Eliminate long wait times—no more 12-week shipping delays

✅ Keep older machines running—even if parts are discontinued

✅ Print only what you need—reduce waste and inventory costs

Ready to take control of your spare parts? Stop overpaying and start printing. Visit RapidMade.com to get started today!