Optimizing Academic Research Fabrication: How Precision CNC Turning Services Prevent Costly Errors in University Engineering Projects

Figure 1: Advanced CNC turning infrastructure in academic settings enables 35% faster prototyping cycles while maintaining ±0.005mm precision, helping university research teams avoid costly errors and timeline overruns.

Introduction

University engineering and research projects consistently face a critical bottleneck: the fabrication of custom components. Challenges like delivery delays, budget overruns, and insufficient part accuracy frequently derail research timelines and compromise data integrity. The root cause often lies in a disconnect between design intent and manufacturing capability, where general-purpose suppliers fail to meet the specialized demands of academic projects, which require low volumes, high precision, and rapid iteration.

This article explores how leveraging professional precision CNC turning services provides a systematic solution. By integrating standardized processes, expert material science, and design for manufacturability (DFM) principles, these services ensure research projects proceed efficiently and reliably. The following sections will detail the key applications and best practices for integrating CNC turning into an academic environment.

What Are the Common Challenges in Sourcing Custom Components for University Research Projects?

Sourcing custom parts for academic work presents unique obstacles distinct from those in high-volume industrial production. Recognizing these challenges is the first step toward mitigating them.

1. Budget Constraints and the “Small Batch” Penalty

University grants and departmental budgets are often limited. Many commercial manufacturers are optimized for large production runs, making small-batch prototyping economically unattractive to them. This can lead to exorbitant pricing or outright refusal to provide a quote, forcing researchers to resort to inferior prototyping methods that lack the required precision for valid experimental results.

2. Tight Timelines and Inconsistent Communication

Grant deadlines, conference dates, and academic semesters frequently constrain research schedules. Delays in partial delivery can have cascading effects, delaying entire research cycles. Furthermore, suppliers unfamiliar with academic workflows may lack the responsive communication needed to address design queries or modifications, creating frustrating bottlenecks quickly.

3. Geometric Complexity and Standards Compliance

Projects ranging from microfluidic devices to aerospace actuators often involve complex geometries with tight tolerances. As outlined in the ASME Y14.5 Dimensioning and Tolerancing standard, clear communication of geometric requirements is essential. Without a supplier capable of interpreting and adhering to these standards, parts may be manufactured to incorrect datums or with unacceptable form variations, rendering them useless for publication-grade research.

How Does Precision CNC Turning Enhance Accuracy and Efficiency in Research Prototyping?

Precision CNC turning transforms research prototyping by introducing a level of accuracy, repeatability, and speed unattainable with manual or basic machining methods.

- The Principle of Automated Precision: CNC turning operates on computer-controlled commands that dictate the movement of cutting tools with exceptional accuracy, often achieving tolerances within ±0.005 mm. This automated process eliminates the variability inherent in manual machining, ensuring that every part in a batch, whether for a single experiment or a multi-student lab course, is virtually identical. This repeatability is fundamental for generating statistically significant scientific data.

- Reducing Human Error and Accelerating Iteration: Once the digital design (CAD model) is finalized and the machine is programmed (CAM), the production process is highly automated. This significantly reduces the risk of human error. More importantly, it allows for rapid design iteration. If a design flaw is discovered during testing, modifying the digital file and producing a revised version is straightforward and fast, enabling an iterative design process that is crucial for research and development.

- Practical Application: A Robotics Component Case: Consider a university team developing a custom robotic gripper. The design requires precise aluminum axles with specific bearing seats. Using a professional service, the team uploads its CAD model and receives DFM feedback recommending a slight chamfer to facilitate assembly. The parts are machined from a single aluminum block, ensuring concentricity and strength. They are delivered in days, allowing the team to proceed with assembly and testing without losing a critical week of their semester.

What Materials and Design Considerations Maximize CNC Turning Success for Academic Applications?

Success in CNC turning is not solely about the machine; it’s about the intelligent selection of materials and the application of sound design principles tailored to academic needs.

1. Strategic Material Selection for Performance and Cost

Choosing the right material is a balance between mechanical properties, machinability, and cost. For most academic prototypes, aluminum alloys offer an excellent combination of light weight, high strength, and ease of machining, resulting in faster turnaround and lower cost. For applications requiring higher strength or corrosion resistance, such as fluidic systems, stainless steel may be appropriate. Researchers can consult resources like this guide to CNC turning materials to make informed decisions based on their project’s specific thermal, electrical, and mechanical requirements.

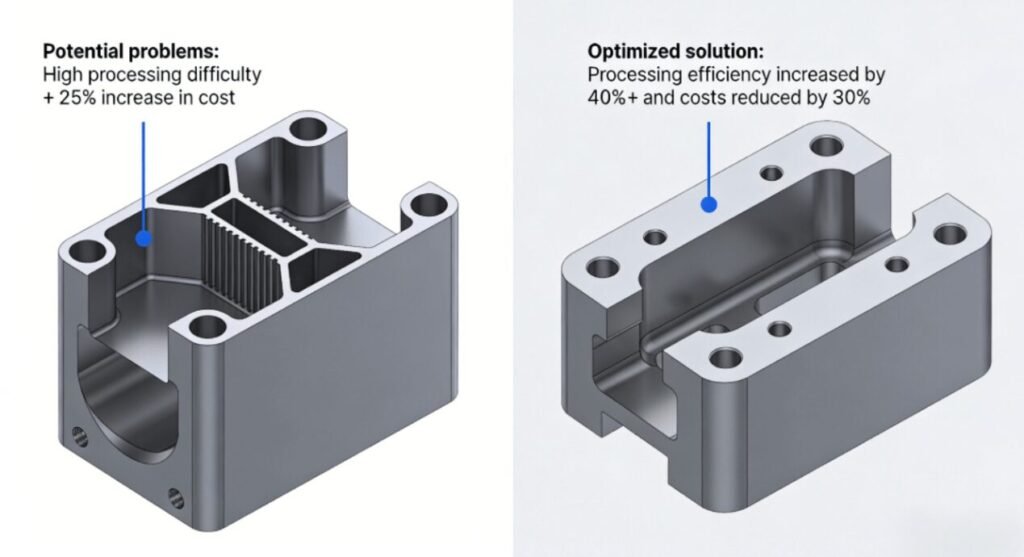

2. Implementing Design for Manufacturability (DFM) Principles

DFM is a collaborative approach that optimizes a part’s design for the chosen manufacturing process. For CNC turning, simple DFM adjustments can dramatically reduce cost and lead time. Key principles include specifying standard hole sizes compatible with common tooling, avoiding unnecessarily tight tolerances that increase costs, and designing features that can be machined in a single setup. Adhering to DFM, supported by a quality management system such as ISO 9001, ensures that parts are not only designed well but also produced efficiently and consistently.

Figure 2: DFM and material selection optimization analysis – implementing design improvements and strategic material choice can increase machining efficiency by 40% while reducing academic project costs by 30%.

How Can Quality Certifications Like ISO 9001 and AS9100D Ensure Reliability in Research Fabrication?

For academic research, where the validity of results is paramount, the quality and traceability of custom components are non-negotiable. This is where a supplier’s certifications become directly relevant to research integrity.

1. Systematic Process Control and Error Prevention

Certifications such as ISO 9001 are not merely plaques on a wall; they represent a documented system of process controls. A certified supplier follows standardized procedures for everything from initial quote generation to final inspection. This systematic approach minimizes deviations and prevents errors, ensuring that the parts you receive match the design you submitted. This level of process control is invaluable for research that requires exact replication of components.

2. Full Traceability and Documentation Support

In fields such as aerospace and medical device research (where standards such as AS9100D and ISO 13485 are relevant), full traceability of materials and processes is mandatory. A certified partner provides the necessary documentation, including material certifications and inspection reports. This documentation is often required for publishing research or for regulatory submissions, providing a clear audit trail from raw material to finished part.

What Are the Cost and Time Benefits of Integrating CNC Turning into University Workflows?

Viewing precision CNC turning as a strategic partnership rather than a simple transaction reveals significant long-term benefits for academic institutions.

- The True Economics of Low-Volume Production: While the unit cost of a CNC-turned part may be higher than a mass-produced injection-molded item, it is exceptionally cost-effective for low volumes. There are no upfront tooling costs, making it ideal for prototypes and small-batch production. Economic efficiency derives from eliminating the need for multiple fixtures and setups, a hallmark of advanced turning centers.

- Dramatic Reductions in Time-to-Prototype: The digital nature of CNC turning drastically compresses lead times. A well-defined part can often be quoted within hours and shipped within a few days. This accelerated timeline enables students and research teams to test ideas quickly, fail fast, and iterate more rapidly, thereby fundamentally enhancing the pace of innovation within academic cycles. Case studies have demonstrated cost reductions of up to 30% and time savings of more than 35% relative to traditional outsourcing or in-house manual machining.

How to Select a CNC Turning Partner for Long-Term Academic Collaboration?

Choosing the right manufacturing partner is critical for building a sustainable and prosperous research fabrication capability.

1. Evaluating Technical Capability and Communication

Look for a partner with a proven track record in handling complex, low-volume projects. Key indicators include their equipment list, expertise in your required materials, and their willingness to provide constructive DFM feedback. Their communication style should be proactive and transparent, with a clear understanding of academic constraints and goals.

2. Commitment to Quality and Sustainability

Prioritize partners with relevant quality certifications, as discussed previously. Furthermore, a commitment to sustainable manufacturing, as reflected in certifications such as ISO 14001, aligns with the values of many academic institutions. A partner that views the relationship as a long-term collaboration will invest in understanding your needs and consistently deliver value, ensuring the success of countless future projects.

READ MORE

Conclusion

Precision CNC turning services provide a robust solution to the persistent fabrication challenges encountered in university engineering projects. By delivering unmatched accuracy, enabling rapid iteration, and ensuring reliability through standardized processes and quality certifications, this technology empowers researchers and students to focus on innovation rather than manufacturing obstacles. Integrating these services into academic workflows not only prevents costly errors but also accelerates the research and development cycle, turning ambitious concepts into high-quality, tangible prototypes.

FAQs

Q1: What is the typical lead time for CNC turning parts in academic projects?

A: Lead times vary by complexity, but standard CNC turning services often deliver parts in 3-5 days for prototypes. This operational efficiency helps university teams meet tight research deadlines without compromising quality. Factors like material availability and design optimization can influence timelines.

Q2: How does CNC turning handle complex geometries for research applications?

A: Advanced CNC turning centers use multi-axis capabilities and live tooling to achieve intricate shapes like threads, grooves, and contours. This geometric versatility is ideal for academic projects requiring high precision, such as custom sensors or medical device components, ensuring dimensional accuracy per design specs.

Q3: What materials are most suitable for CNC turning in university settings?

A: Common materials include aluminum for lightweight prototypes and stainless steel for durability. Engineers should select materials based on project needs—e.g., thermal resistance or cost—and consult materials science resources to ensure compatibility with research goals.

Q4: How can design for manufacturing (DFM) principles reduce costs in academic CNC turning?

A: DFM optimizes designs for easier machining, minimizing waste and tool changes. By adhering to guidelines such as standard tolerances and simplified geometries, universities can lower production expenses by up to 30% while maintaining part functionality and quality.

Q5: What quality assurances should researchers expect from a CNC turning provider?

A: Providers should offer certifications like ISO 9001, detailed inspection reports, and first-article checks. These measures ensure that parts meet academic standards, with documentation provided to support traceability and compliance with research publication requirements.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company dedicated to helping engineers and researchers solve complex part challenges in academic, aerospace, and medical industries. Supported by a robust quality management system, the team ensures reliable, high-quality manufacturing solutions. For more insights and to optimize your next project, contact them today for a free, no-obligation project review and DFM analysis.