Breaking Materials to Build Stronger Ones: The Role of Pendulum Impact Testers

Modern infrastructure depends on materials that can resist sudden shocks. Different specializations rely on metals and plastics designed not just to carry weight, but also to withstand impacts. To determine whether a material will shatter or absorb impact, engineers use pendulum impact testers. These machines appear simple: a swinging arm, a specimen, and a single strike. Yet the data they provide often decides whether a structure will remain safe or fail under pressure.

Impact testing is now part of routine material evaluation. Laboratories use pendulum methods not only to verify compliance with international standards but also to compare how metals, plastics, and composites behave under sudden loads. What began as a simple way to measure absorbed energy has developed into a consistent benchmark for both research and production.

That benchmark is visible in multiple sectors. Laboratories and production facilities use it to verify that metals, plastics, and composites can withstand sudden forces. Even packaging lines employ pendulum methods to assess how materials react when dropped or struck. The variety of applications demonstrates how a simple testing method continues to meet modern demands without losing relevance.

The simplicity of the setup is what makes it powerful. A controlled strike under standardized conditions provides a direct measure of energy absorption that no simulation can fully predict. That clarity helps engineers and regulators set safety thresholds with confidence.

How Pendulum Impact Testers Work

The principle behind pendulum testing is straightforward. A pendulum of known mass and length is released from a fixed height and strikes the specimen. The energy absorbed by the sample is calculated from the difference in height before and after the swing. This measurement reveals how much energy the material dissipates during fracture.

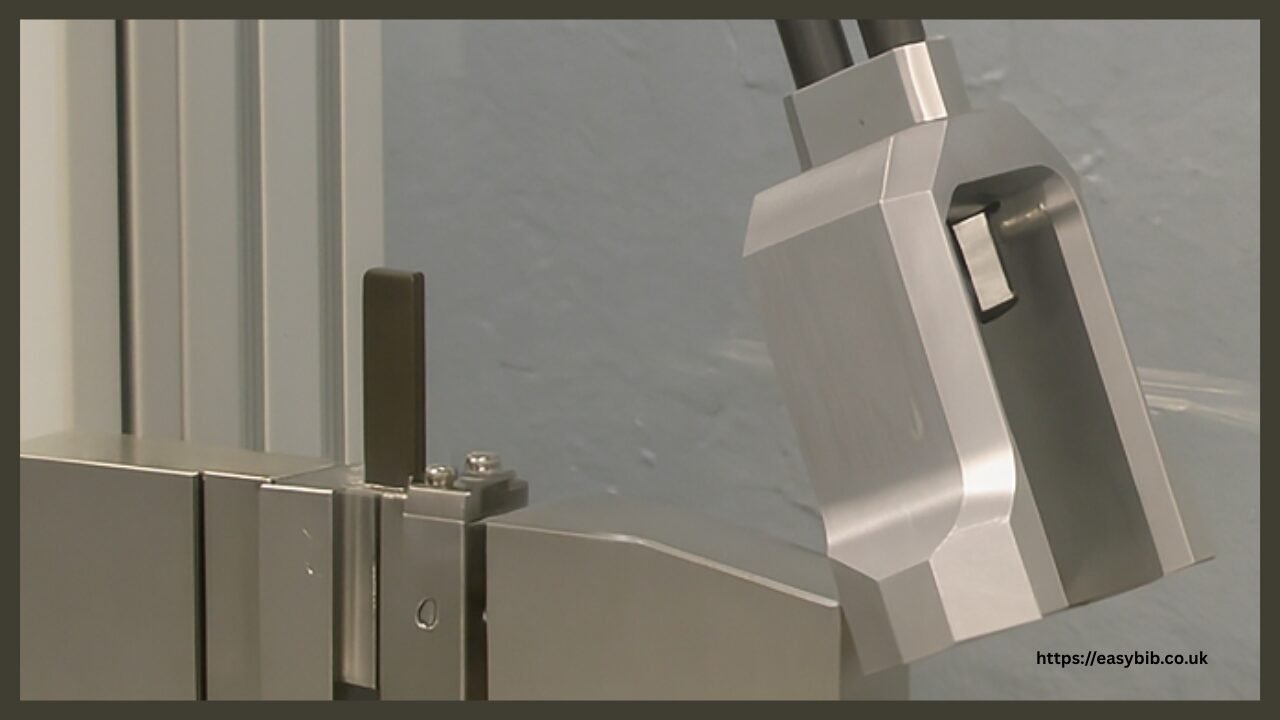

Modern testers are more precise than their early counterparts. They include rigid frames, calibrated scales, and electronic sensors that capture impact data in real time. Some machines record not just the total absorbed energy but also the force-time curve of the fracture, showing exactly how the crack propagates through the material.

Typical plastic-testing equipment operates at a few joules, while metal-testing machines deliver several hundred joules. For instance, steels used in bridges may be tested at 300 joules, while polymer samples may only require 20. This flexibility allows the same principle to be applied across very different industries.

Specimens are usually prepared with a notch, a small cut that acts as a stress concentrator. The notch ensures fractures start from a fixed point in every test, enabling reproducibility. Different notch shapes, such as V-notches or U-notches, are selected depending on the material and the standards being followed.

High absorption indicates ductility and resistance to brittle failure. Low absorption shows that the material fractures easily, with little capacity to deform. The test, therefore, helps engineers predict performance in real-world conditions where sudden shocks or crashes may occur.

Charpy and Izod: Two Approaches to Impact Testing

Pendulum impact testing comes in two widely used forms: Charpy and Izod. Both methods are internationally standardized, ensuring results are reliable and comparable across laboratories.

In the Charpy method, the specimen rests horizontally on two supports while the pendulum strikes at the center. This setup measures how the material behaves when loaded across its span, similar to a beam subjected to a sudden load. The standard specimen length is 55 millimeters, with a V-notch or U-notch cut into the center. Charpy tests are widespread for structural steels, aluminum alloys, and other metals where failure under bending loads is a concern.

The Izod method positions the specimen vertically, clamped at one end like a cantilever. The pendulum strikes near the top edge above the notch. Because loading conditions vary, Izod testing is often used for plastics, polymers, and composite materials. It provides data on how materials behave when struck along edges or corners, which is relevant to consumer products, casings, and safety equipment.

Although the two methods differ in geometry, they are guided by the same principles: controlled specimen size, standardized notch shapes, and consistent striking energy. Standards such as ASTM E23 and ISO 148 for Charpy tests, or ASTM D256 for Izod tests, define how tests must be conducted to allow results to be compared worldwide.

Together, Charpy and Izod provide a complementary picture. Charpy excels at testing metals under bending loads, while Izod highlights edge-impact resistance in plastics. Engineers select the method based on material type and the failure scenarios they need to study.

Why Impact Testing Still Shapes Modern Safety

Although pendulum testers are not new, their relevance remains strong. The information they provide continues to guide decisions in industries where safety margins are non-negotiable.

Impact data guides design choices wherever safety margins are critical. Engineers use these results to study how fractures start and spread, and manufacturers apply them to confirm that everyday materials and specialized components can withstand sudden shocks without breaking apart. Some products are also tested to determine whether plastics or polymers retain their strength under sudden shocks.

In each case, the data is not about preventing minor defects but about confirming that fractures will not develop into larger structural failures. A brittle break in the wrong component can cascade into larger accidents. Pendulum impact testing provides a precise and controlled method for anticipating such risks.

READ MORE

Simple Tools, Lasting Relevance

Pendulum impact testers may look outdated next to advanced computer simulations and digital testing machines. Still, they remain a cornerstone of material science. Their strength lies in their simplicity: a direct measurement of how a material breaks under sudden force.

Far from being replaced, these machines complement modern analysis by grounding predictions in physical reality. By continuing to use them, industries secure knowledge about material performance that no software model can fully replicate.

Beyond their continued use in quality control, pendulum impact testers also shape the development of new alloys and polymers. Researchers fine-tune material compositions by comparing how small chemical changes affect fracture behavior. This feedback loop links laboratory discovery to industrial application, closing the gap between innovation and deployment.